Browse Products by Sector

Container ShippingContainer Equipment Assets

Ports and Terminals

Dry Bulk Shipping

Tanker Shipping

Gas Shipping

Specialised Shipping

Airfreight Transport

Logistics Management

Ship Operations and Management

Other popular areas

Browse subscriptions by Sector

Container ShippingPorts and Terminals

Dry Bulk Shipping

LPG Shipping

LNG Shipping

Crude Tanker Shipping

Product Tanker Shipping

Financial Advisory

Valuations

Drewry Financial Research Services Ltd is authorised by the UK Financial Conduct Authority (FCA).

Our Experience

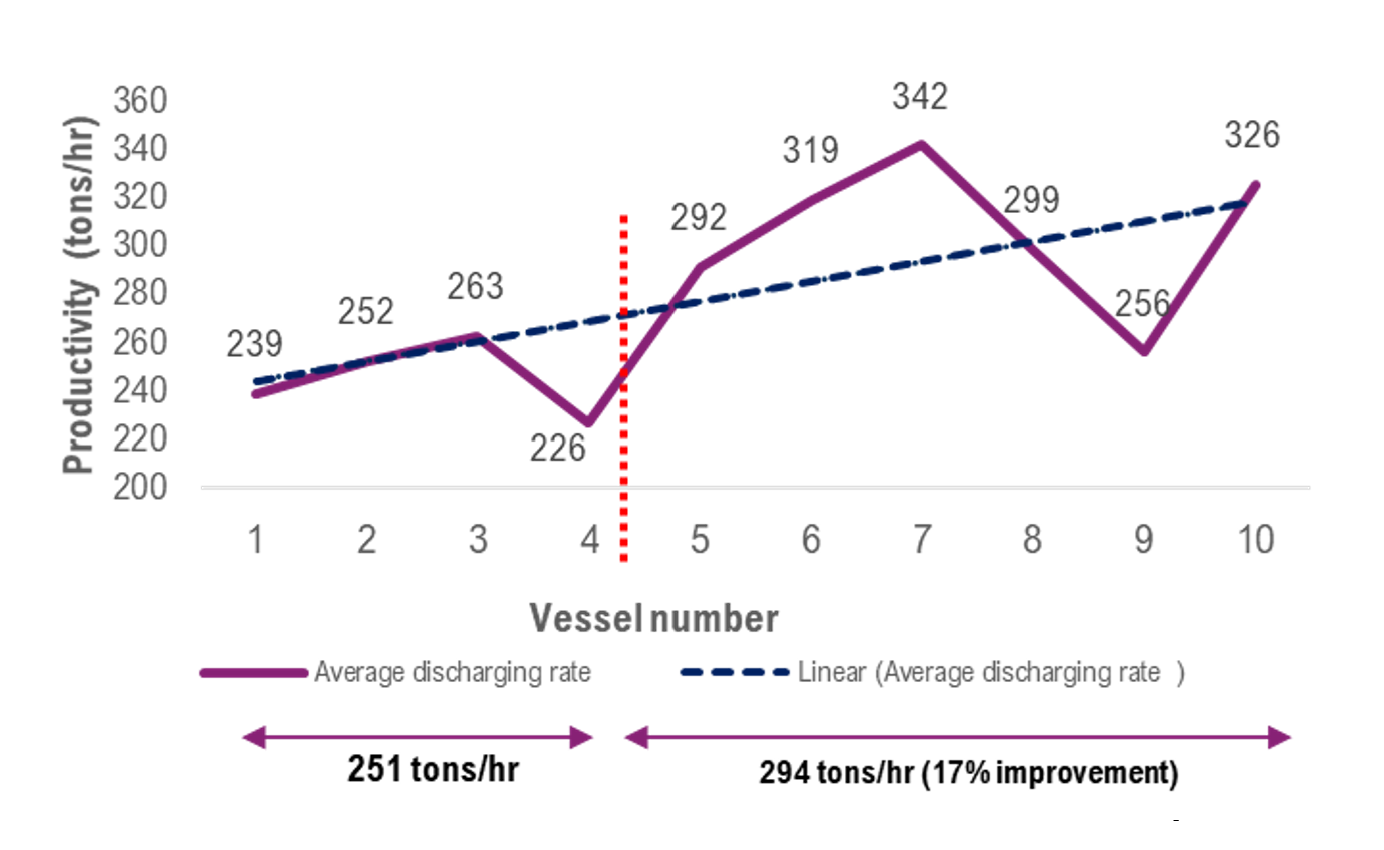

Productivity improvement in cement discharging

Client: Major dry bulk port in Singapore

At a port in Singapore, the productivity of the cement berth operated by the port was higher than that of the berth operated by the client. The port wanted to improve the productivity of the cement berth operated by the client, so that berth space could be utilized for other vessels.

Approach

- Operation on board the vessel was observed to understand why the productivity was low and evaluate the scope for improvement.

- It was noted that when the discharging was from Hold 1, the speed of the conveyor belt was reduced purposefully as there was a turn on the convey belt, close to the hold. This was done to prevent cargo spillage near the bend.

- The stowage plan was changed to reduce the quantity of cargo in Hold 1 and increase it in other holds for subsequent loadings.

Result Achieved

- Vessel productivity increased by 17% over a 3 month period following the implementation of the improvements identified and other operational refinements.

More like this

© Copyright 2024 | Drewry Shipping Consultants Limited. All Rights Reserved. Website Terms of Use | Privacy Policy

We use cookies to remember if you are logged into this website and provide you with the best online experience. By continuing to use our website you are agreeing to our use of cookies. Click on this banner message if you would like to find out more.